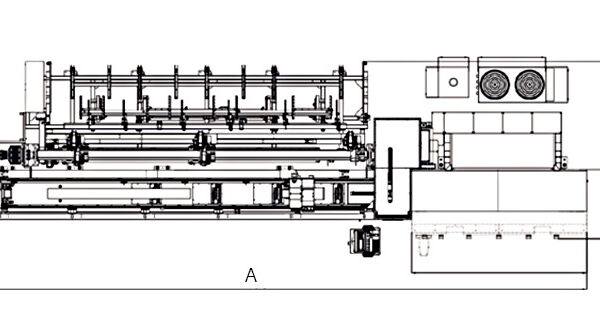

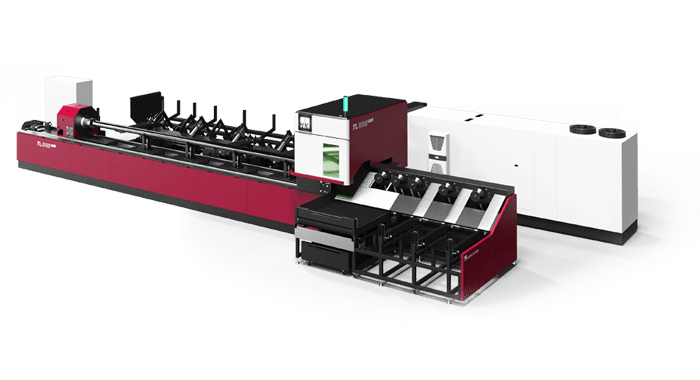

The TL6015 Tube Laser

The TL6015 Tube Laser is a fully automated tube cutting system featuring Auto bundle loading & feeding, Auto rotary chuck clamping, Auto start for laser-cutting, and a part removal station.

Features

- Automated bundle loader

- Tube feeding system

- High speed rotary chuck

- Laser cutting station

- Automated unloading station

- Heavy duty

- SIEMENS 840D control & servo

- PRECITEC cutting head

- IPG or nLight fiber laser resonator

CO₂ / Fiber laser mountable

- Copper and brass tube cutting when fiber laser is mounted